Why food needs to be cooled quickly

It’s important to cool food as quickly as possible after cooking because at room temperature, harmful bacteria can begin to develop. Bacterial contamination can happen within just a couple of hours, which is why finding a way to speed up the cooling process is so vital for the health and safety of you and your customers.

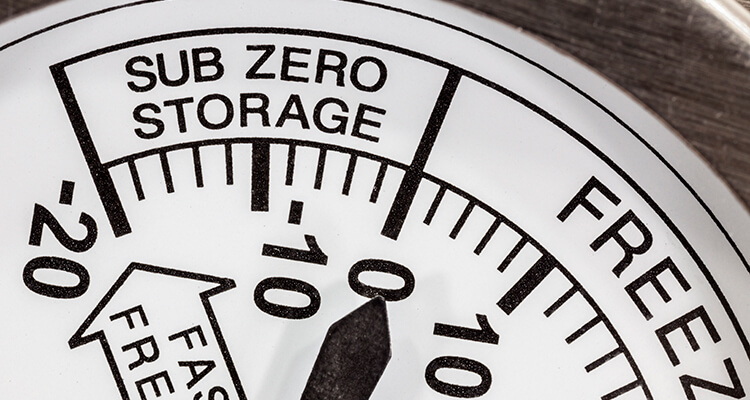

The legal temperature requirement for chilled foods is no warmer than 8°C, although it is recommended that food be stored at a temperature of 5°C or less to ensure both quality and safety. Ideally, cooked food should not be kept out of a refrigerated unit for longer than 90 minutes after cooking, which can be difficult when trying to cool large quantities of food.

Why you should use a blast chiller

It’s common knowledge that hot food should not be put straight into refrigeration directly after cooking, as this can bring down the temperature of the entire unit and create a potentially dangerous atmosphere due to condensation.

Unfortunately, this leaves caterers and restaurants in a tricky situation. Food needs to be chilled ASAP after cooking, if it isn’t going to be consumed immediately but room temperature food poses a health and safety risk. Thankfully, there is a safe and easy way to cool down large batches of food, without risking the health of your customers.

Blast chillers are specifically designed to cool down bulk quantities of food quickly and effectively in a temperature controlled environment. This ensures that food is not left out in unsanitary conditions unnecessarily and doesn’t compromise other chilled foods already in refrigeration. Whilst there are many tips and tricks chefs use to cool down cooked food, none are as effective as using a blast chiller.

Who can benefit from blast chilling?

Blast chillers are designed for fast bulk cooling, meaning that they are most suited to catering companies, restaurants and other food organisations that need to prepare food in advance.

As blast chillers are available in a range of sizes most businesses, whether large or small, can benefit from everything a chiller has to offer. Anything from cooked ready meals to meats, cheese and fish can be cooled in bulk, making them a highly versatile piece of equipment.

Tips for cooling food effectively

Using a blast chiller is the best way to cool large batches of food quickly, without risking contamination. However, once you have your blast chiller, there are a few things you can do to ensure food is chilled and stored safely.

- Only fill to capacity – Filling your blast chiller above the capacity stated will damage the effectiveness of your unit and can slow the cooling process, leading the bacterial development.

- Regularly check temperatures – It’s important to regularly check the temperature of your blast chiller to ensure that everything is working correctly. Not doing so could lead to a temperature failure going unnoticed and potentially contaminated food being served to customers.

- Rotate food regularly – To ensure that old food doesn’t get left in your chiller, use a rotation system that ensures older food is moved to the front of the unit before new food is put in.

- Clean your chiller regularly – Blast chillers are safe and hygienic environments but even they aren’t immune to leaks and spills. Remember to clean out your unit regularly to avoid cross contamination.